MDF or medium-density fiberboard is a fairly good building material, a type of engineered wood. That being said, one drawback it has is that it’s not very water-resistant. However, you can make it more water-resistant by sealing it. A material of choice for this task is often polyurethane.

This is what we are here to teach you today – how to seal MDF with polyurethane.

Is Polyurethane the Best Material for Sealing MDF?

There are actually many different materials or substances that can be used to seal medium-density fiberboard. For instance, some people will use PVA glue, also known as carpenter’s glue. It’s a good way to seal the MDF, although it’s not the most moisture-resistant material in the world.

There are actually many different materials or substances that can be used to seal medium-density fiberboard. For instance, some people will use PVA glue, also known as carpenter’s glue. It’s a good way to seal the MDF, although it’s not the most moisture-resistant material in the world.

For this reason, many people also use combinations of primer and drywall compound or just some oil-based primers alone. Remember, whatever sealant you use here, the point is for it to be water-resistant, or preferably even waterproof.

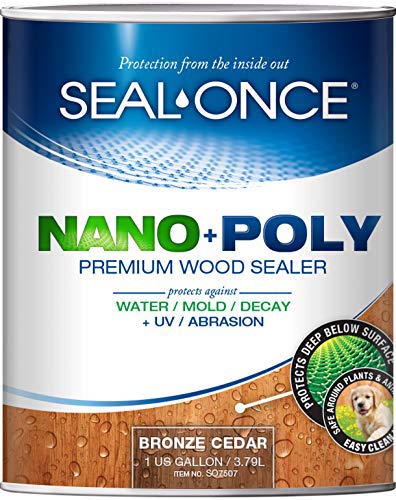

For this reason, you guessed it, polyurethane sealant is generally considered the best material. For those of you who don’t know, polyurethane is actually a special type of plastic. Yes, plastic is 100% waterproof. Therefore, when you seal medium-density fiberboard with a polyurethane sealant, it becomes more or less 100% waterproof.

With that said, polyurethane sealant alone might not be enough to achieve the desired results. For this reason, many people actually start by using a primer.

How to Seal MDF with Polyurethane

As we mentioned above, you actually want to use a special type of primer before you use the polyurethane sealant to seal your medium-density fiberboard sheets. Follow the steps exactly as listed below in order to get the job done

Step 1: Gather Your Materials

You are first going to need to gather all of the necessary materials. This includes 150 grit sandpaper, 220 grit sandpaper, a dust vacuum, white primer, a synthetic brush, the polyurethane sealant of choice, and some rags and other materials to cover the surface that you are working on.

Once you have gathered your materials, you can then move on to sealing your MDF panels with polyurethane.

Step 2: Sand the MDF Sheets

Use 150 grit sandpaper to sand all areas of the medium-density fiberboard that you want to seal. Make sure that you cover every last square inch, and move your sandpaper in a circular motion. You want that MDF to be as smooth as possible for sealing. You now want to either blow off any remaining dust or use a dust vacuum to remove any debris and dust.

Step 3: Apply the Primer

Using either a fine brush or a paint sprayer, prime the MDF with your primer of choice. Once again, make sure to cover every square inch. You now need to wait for anywhere between 30 to 60 minutes until it dries. Just touch it with your finger to make sure that it is 100% dry before moving on to the next step.

Step 4: Repeat Steps 2 and 3

Now, you are going to repeat step number two. Here except for the fact that you are going to use 220 grit sandpaper instead of 150 grit sandpaper, the process is the same. Sand the already once primed MDF until it is very smooth. Once again, use a vacuum or a blower to remove any remaining dust or debris.

Now, you are going to repeat step number three. Use either a brush or a paint sprayer to spray a layer of primer onto the sheet of medium density fiberboard. You now want to wait for another 30 to 60 minutes for this coat to dry. Once it is totally dry, use a damp rag to wipe away any remaining particles.

Step 5: Apply the Polyurethane

You are now going to use a soft-bristled synthetic brush to apply a coat of polyurethane to the medium-density fiberboard. Make sure that your strokes are very smooth and even. Once the layer has been applied, you want to let it dry for up to an hour. You then want to apply a second coat of polyurethane sealant. Once it is totally dry, your MDF is ready to go.

Mistakes to Avoid, Tips & Tricks

Before you go, here are a few tips to make the job easier:

- Whenever applying any kind of primer, paint, or sealant, make sure that there is no debris present. You don’t want dust or debris present under those layers.

- Always make sure that previous layers of sealant or material are dry before applying another layer. Applying a new layer before the first one has dried is not going to work out well.

- Make sure that you are working in a dry and well-ventilated area. Extreme moisture or a lack of ventilation can pose a variety of problems when it comes to this process.

Summary

There you have it, folks, you should now know everything there is to know about sealing medium-density fiberboard with polyurethane. As you can see, it’s a fast and easy process, and it also comes with great benefits.