18

Whether you’re engaged in professional or DIY construction work, there’s a good chance that you’ve had a circular saw in hand on a couple of occasions. That makes sense given the power and versatility offered by these particular power saws. Much of that power and versatility derives from a circular saw’s blades, which can be switched in and out depending on the task at hand.

If you’re wondering which one to choose for your next project, then you’ve come to the right place.

This guide will highlight eight of the most common and practical circular saw blades used by professional and amateur craftsmen alike. This guide will even teach you about what to look for when selecting a circular saw blade based upon its physical structure.

What Affects Circular Saw Blade Choice?

Before we jump into describing some circular saw blades, let’s take a moment to define what constitutes the “right” saw blade for our upcoming job.

Of course, the precise parameters of what and how you are trying to saw should guide your choice. But while making that choice, be sure to consider what you intend to cut. After all, circular saw blades for wood and very different than those used to cut stone or tile.

At the same time, be sure to keep in mind the type of cut you intend to make. Some blades offer a cleaner or thinner cut, while others create a rough cut every time. These performance-based metrics can derive from a blade’s specifications, which we’ll discuss more later in this guide.

8 Types of Circular Saw Blades

First, let’s go through the common blade types, though.

Combination Blades

Combination blades are considered the standard when it comes to a circular saw. In fact, there’s a good chance that your unit came with one of these multi-purpose blades right out of the box. That’s because these blades are designed to efficiently cut through most kinds of wood, both with and against the grain.

Combination blades are considered the standard when it comes to a circular saw. In fact, there’s a good chance that your unit came with one of these multi-purpose blades right out of the box. That’s because these blades are designed to efficiently cut through most kinds of wood, both with and against the grain.

To make that happen, these blades feature medium-size teeth and gullets. This ensures that the blade is able to create a moderately clean cut, even while making quick passes.

Combination blades are only designed for cutting wood, however. As such, their versatility should not be used to imply that they can cut through anything like tile or stone.

Paneling Blades

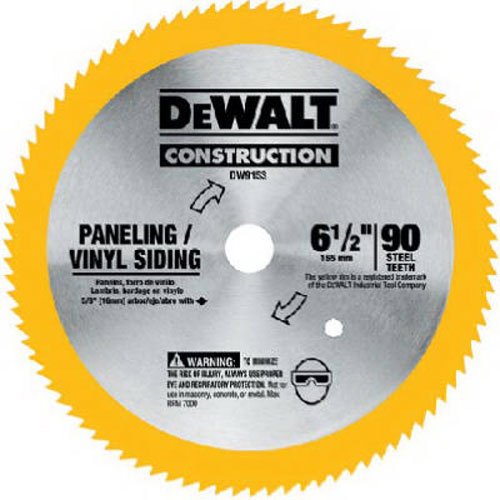

Paneling blades are also a common fixture for woodworkers who regularly need to make extra-thin cuts.

Paneling blades are also a common fixture for woodworkers who regularly need to make extra-thin cuts.

As their name implies, these blades are able to accomplish that task with precision. Not only that, but these blades are by far the best choice for folks looking to slice through veneer, plywood, laminates, plastics, and other light-gauge materials without ruining their structural integrity.

In practice, a paneling blade’s relatively small teeth and shallow gullets allow them to “gently” carve into any of the materials listed above. As such, these blades typically require more time in order to successfully complete a cut.

However, that patience should pay off when you end up with a final product that a general-use blade simply cannot accomplish.

Diamond Blades

Diamond blades are almost exactly what they sound like – a circular saw blade with an edge that is tipped in an abrasive diamond material. These come in a variety of shapes and styles, but they are almost uniformly used to cut through extra-dense materials like stone and tile.

Diamond blades are almost exactly what they sound like – a circular saw blade with an edge that is tipped in an abrasive diamond material. These come in a variety of shapes and styles, but they are almost uniformly used to cut through extra-dense materials like stone and tile.

In that capacity, diamond blades are able to create extremely fine cuts without causing the material’s fragile structure to shatter or chip.

Crosscutting and Ripping Blades

Crosscutting and ripping blades are two sides of the same coin when it comes to circular saws. As their name implies, their structure makes them ideal for making crosscuts and rips, respectively, through lumber.

Crosscutting and ripping blades are two sides of the same coin when it comes to circular saws. As their name implies, their structure makes them ideal for making crosscuts and rips, respectively, through lumber.

Specifically, crosscutting saw blades have more teeth to allow them to more efficiently gouge a plank or board’s horizontal structure. Meanwhile, a ripping blade’s tall, hooked teeth and wide gullets allow them to efficiently draw the saw forward up a plank or board’s lateral length.

Both blade types are worth having on hand when you want a cleaner version of either basic cut.

If you want to more about ripping boards with a circular saw, read this article.

Continuous Rim Blades

Continuous rim blades are the preferred blade type for folks looking to create an extra-clean finish.

Continuous rim blades are the preferred blade type for folks looking to create an extra-clean finish.

That’s because, without any segmented teeth, these blades leave a cut’s inner edge almost as smooth as possible. The majority of continuous rim blades are also diamond-tipped, meaning that they see use in masonry and tile cutting.

In that application, continuous rim blades may be used for either wet or dry cutting.

Segmented Blades

Like their continuous rim cousins, segmented blades are unique because they do not feature any traditional saw teeth.

Like their continuous rim cousins, segmented blades are unique because they do not feature any traditional saw teeth.

Instead, their outer edge is made up of a continuous rim that has been segmented by specialized gullets. This structure (along with diamond-tipping) allows these blades to make an extra aggressive cut per pass.

As such, they see a fair bit of use when cutting concrete, cement, bricks, and the like. Compared to a continuous rim blade, though, a segmented blade’s finish is far rougher.

Abrasive Blades

Abrasive blades are similar in appearance to a continuous rim blade in that they are also free of traditional saw teeth. Instead, these disc blades are made up of a single, continuous piece of abrasive material that provides comparable cutting capacity both at the outer and inner edges.

Abrasive blades are similar in appearance to a continuous rim blade in that they are also free of traditional saw teeth. Instead, these disc blades are made up of a single, continuous piece of abrasive material that provides comparable cutting capacity both at the outer and inner edges.

Due to their aluminum oxide or silicon carbide structure, these blades are often able to effectively cut through materials other blades cannot handle, such as metal.

Dado Blade Sets

Dado blade sets are made up of several chippers and shims that, when affixed together, can spin independently. In practice, this allows a saw to be used to made dado and rabbet cuts with efficiency and accuracy.

Dado blade sets are made up of several chippers and shims that, when affixed together, can spin independently. In practice, this allows a saw to be used to made dado and rabbet cuts with efficiency and accuracy.

However, there’s a common misconception that dado blade sets can be used in a circular saw. They cannot and should not be used in this capacity because they can be very dangerous to the circular saw’s user.

Instead, dado sets should only be used by skilled users when working at a table saw.

See my dado blade set recommendations

Circular Saw Blade Specifications to Consider

As you continue the process of picking out the right saw blade, there are a few key specifications that you should keep in mind.

The first of these is the number of teeth per inch a blade features. Often shortened to “TPI”, a blade’s tooth count can give you a solid idea of its sawing capacity.

When it comes to woodcutting, at least, more teeth often signals a quicker and cleaner cut. Gullet size may also be listed beside a blade’s TPI. Gullet size is less important, but a larger gullet is usually able to channel sawdust out of a cut more effectively.

Also, be sure to check your prospective saw blade’s overall size. Circular saws come in several different sizes, after all. As such, different types of blades will often be offered in several different sizes at once. While they may be interchangeable to an extent, obtaining the right size is crucial, not least because an improper blade size can be dangerous in practice (check our circular saw safety tips).

Summary

All in all, there are quite a few circular saw blade types to choose from in today’s market.

As such, it is important for you to remember what you learned in this guide so that you can quickly determine which type is best suited to your upcoming job. However, you shouldn’t necessarily settle for using just one or two blade types.

To that end, you’ll find yourself prepared for almost any circular sawing job if you have a wide assortment of saw blade options at your disposal. To learn about how to change them, read this article.